Nitrocellulose is the reactant of nature cellulose and nitrate acid. It is a kind of white flocculus or flake fiber; which is an inflammable solid whose molecular formula is [C6H7O2(OH)3-r (ONO2)r]n. Acid, alkali, oxidant, reductant or heat and direct sunlight will make unfavorable affection on the quality of nitrocellulose. it is a wonderful product that helps make the life around us more colorful. It is a very important material in many fields, Nitrocellulose (NC) is mainly classified as industrious nitrocellulose (INC) and energetic Nitrocellulose (ENC) . Industrial NC has wide usages, NC for coating can be applied in producing different types of coatings, stencil paper, ink, varnished cloth, sealing cover, binder, leather oil, nail polish, and so on. NC for Celluloid is mainly used for table-tennis ball and celluloid adornment products.

1.1 according to specification the industrial nitrocellulose should contain at least 25% of wetting agents that water or alcohols are usually used as. SNC can provide nitrocellulose products containing different kinds of wetting agents such as water, ethanol, isopropanol, n-butanol, etc.

SNC also provides nitrocellulose chips, a flaky product from plasticized NC with (no less than) 18% of plasticizers, such as DBP, DOP, etc. after replacing the water in NC.

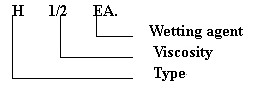

1.2 The nitrocellulose products can be classified into H-type and L-type based on their nitrogen content and, in turn, subdivided into different grades according to the viscosity in the standard NC Solution (see Products Specifications).

Features of H-type

To form a tougher film.

Evaporate its solvents faster than L-type.

Be diluted easily with alcohols, aromatic and aliphatic solvents.

Possess more excellent mechanical performances.

Since it can be readily dissolved into esters solvents, H-type product is also called ester-soluble nitrocellulose.

Features of L-type

Form a thermoplastic film. Dissolve into large amounts of alcohols (such as methanol or ethanol) with small amount of esters.

Be diluted easily by aromatic solvents.

L-type product is also called alcohol-soluble nitrocellulose since it can be readily dissolved into alcohols

| Type | Specification (S) |

Nitrogen content(%) | Viscosity range | |||

| A | B | C | ||||

| L | 1/8 | 10.7-11.4 | 1.7-2.8 | |||

| 1/4a | 3.1-4.9 | |||||

| 1/4b | 5.0-8.0 | |||||

| 1/2a | 3.0-6.0 | |||||

| 1/2b | 6.1-8.4 | |||||

| H | 1/32 | 11.5-12.2 | 0.6-1.0 | |||

| 1/16 | 1.1-1.6 | |||||

| 1/8a | 1.7-2.2- | |||||

| 1/8b | 2.3-2.8 | |||||

| 1/4a | 3.1-4.9 | |||||

| 1/4b | 5.0-8.0 | |||||

| 1/4c | 8.1-10.0 | |||||

| 1/2a | 3.0-6.0 | |||||

| 1/2b | 6.1-8.4 | |||||

| 1 | 8.5-16.0 | |||||

| 5 | 4.0-7.5 | |||||

| 10 | 8-15 | |||||

| 20 | 16-25 | |||||

| 30 | 26-35 | |||||

| 40 | 36-50 | |||||

| 60 | 51-70 | |||||

| 80 | 71-100 | |||||

| 120 | 101-135 | |||||

| 300 | 220-350 | |||||

| 800 | 600-1000 | |||||

| 1500 | 1200-2000 | |||||

| Type | Brand | Ball-falling time (sec) | Concentration (100%) |

Type | Brand | Ball-falling time (sec) | Concentration (%) |

| L | 1/8 | 1.7-3.0 | 25.0 | H | 20 | 16-25 | 12.2 |

| L | 1/4 | 3.5-6.5 | 25.0 | H | 30 | 26-35 | 12.2 |

| L | 1/2 | 3.0-6.0 | 25.0 | H | 40 | 36-50 | 12.2 |

| H | 1/16 | 1.0-1.6 | 25.0 | H | 60 | 51-70 | 12.2 |

| H | 1/8 | 1.7-3.0 | 25.0 | H | 80 | 71-100 | 12.2 |

| H | 1/4 | 3.5-6.5 | 25.0 | H | 120 | 101-135 | 12.2 |

| H | 1/2 | 3.0-6.0 | 20.0 | H | 150 | 136-210 | 12.2 |

| H | 1 | 8.5-16.0 | 20.0 | H | 300 | 220-350 | 12.2 |

| H | 5 | 4.0-7.5 | 12.2 | H | 800 | 600-1000 | 12.2 |

| H | 10 | 8-15 | 12.2 | 12.2 |

| Item | UNT | Index | Item | UNT | Index |

| NC solution | % | H ≥93 | Heat test at 80 (°C) | Min | ≥10 |

| Transparent | L ≥93 | Explosive | °C | ≥180 | |

| Whiteness | % | ≥86 | Ash content | % | ≤0.2 |

| acid (as sulfuric acid) | % | 1.16 Sec 1/18 ≤0.08 | Moisture test | No turbidty &mbdng indicator | |

| 1/4 Sec≤0.07 | Damping agents content | % | 28-32 | ||

| other ≤0.07 |

Note: 1, there is no necessary to do moisture test to NC damping with water. If the customer has any special requirement for viscosity or other items decision should be made by negotiation between the seller and buyer.

| Type | Brands | Type | Brands | Type | Brands |

| H | 1/4S | H | 20S | L | 1/2S |

| H | 1/2S | H | 25-30S | L | 5S |

| H | 1S | H | 30-40S | M | 1/4S |

| H | 5S | H | 60S | M | 1/2S |

| H | 15-20S | L | 1/4S | M | 1S |

| Items | Unit | Contents |

| Nitrocellulose | % | Remaining |

| DOP | % | 18±2 |

| Water | % | ≤2 |